Open-Front Capability in a Powerful Four-Post Lift

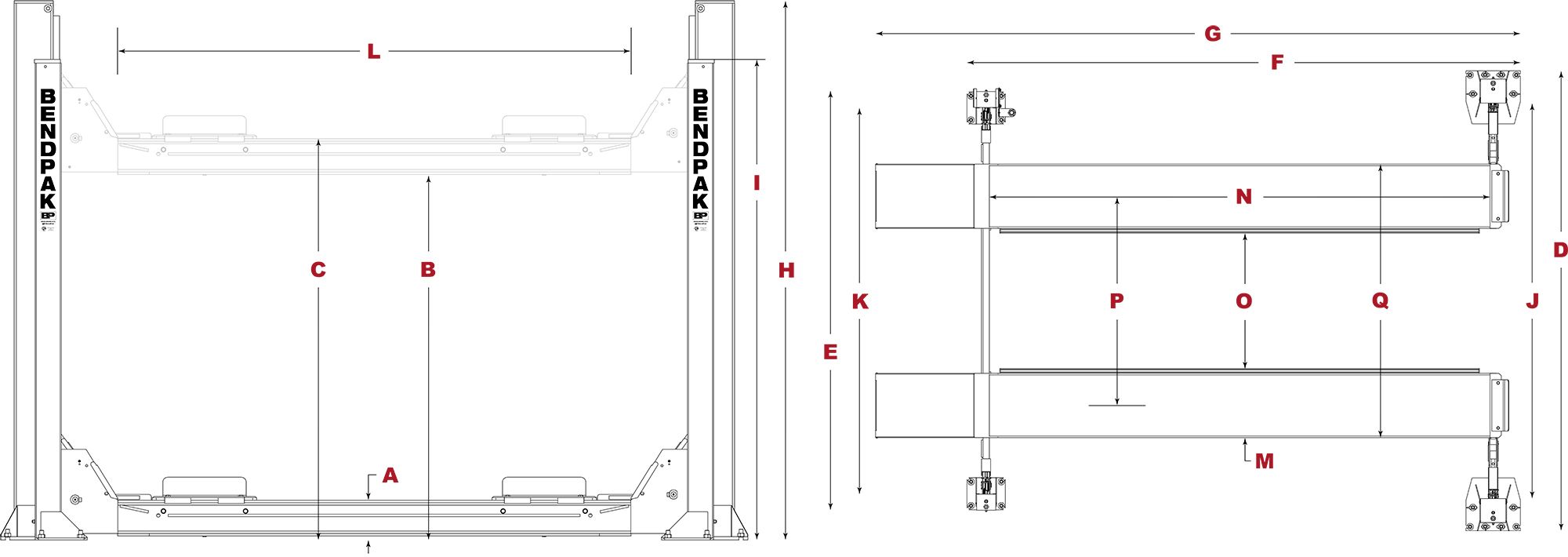

The HDSO14P is an open-front four-post lift that features clear entry upfront, providing easy vehicle access. A generous 14,000-lb. lifting capacity and extended runways allow you to service a wide variety of vehicles, ranging from small cars to full-size trucks.

Open-front design

We engineered the HDSO14P without a front cross bar, so operators can easily enter and exit from beneath the vehicle. Now the process of front-end adjustment becomes quick and trouble-free. This model is a must-have for busy alignment bays.

Patented, adjustable front outrigger tubes

For precise front-lift leveling, nothing beats our patented adjustable front outrigger tubes. The infinitely adjustable pitch compensates for excessive loads and unlevel floors.

Dependable design

Four heavy-duty, high-quality, stainless steel lifting cables and a single hydraulic cylinder mounted underneath the runway make this lift the most durable, maintenance-free lifting system on the market.

Oversize dual-hub cable sheaves

Huge 10.5” diameter cable sheaves within the runway and cross tubes work with massive 2.25” diameter sheave axles to improve cable wear and critical component lifespan. Dual‐hub cable sheaves reduce stress, fatigue and wear. Naturally, this means a lot less money in service-related expenses down the road.

Multi-level locking positions

The HDSO14P is equipped with multiple adjustable height locking positions for variable-height parking. A convenient push-button pneumatic safety lock control releases all four independent safety locks simultaneously.

Heavy-duty aircraft cable

Each lift is supplied with four high-quality 1/2” diameter, 6 x 25 stainless steel lifting cables rated at 14,400 lbs. each. The combined rating of these cables is more than 411% of the maximum lifting capacity of the entire lift! This aircraft‐quality cable was specifically designed for lifting applications and provides a great balance between abrasion resistance and fatigue. And we make sure it looks tidy too—all lifting cables are fully enclosed within the lift structure itself.

Maintenance-free electric hydraulic

A maintenance‐free electric hydraulic power system assures ultimate dependability.

Grease nipples

Grease nipples are located on every sheave and sheave axle to make lubrication maintenance a breeze.

Electric / hydraulic power system

We incorporate maintenance-free electric hydraulic power systems into each lift for ultimate dependability, and all controls are conveniently located within close reach.

Large base plates

12” x 10” base plates provide a solid foundation for the HDSO14P.

Longer approach ramps

These approach ramps were designed a little longer to help when loading low ground-clearance vehicles. It’s the little bit that makes a big difference.

Integrated design

Lifting cables, airlines, safety latches and sheaves are all fully enclosed.

Integrated hydraulic flow

An integrated hydraulic flow restrictor provides a controlled descent in the unlikely event of an unexpected hose rupture.

Automatic safety locks

Aircraft-quality stainless steel and aluminum pneumatic cylinders release all four locks simultaneously with the simple push of a button. The spring-loaded safety locks automatically engage continuously as the lift is raised. For added safety, a secondary lock system acts as a slack-cable device to engage in the unlikely event of cable failure.

Optional 7,000-lb. capacity rolling jacks

The optional 7,000-lb. capacity rolling bridge jack (the RJ7W) lets operators perform full wheel and brake service to vehicles. They sit along the inner edges of each runway, engage the lift points and quickly lift the wheels off the ramps. These are essential tools for anyone who wants to get the most out of their four-post lift.

- 14,000-lb. lifting capacity

- CE Approved and Certified. Meets or exceeds the standards prescribed by European Standard EN 1493

- Huge cable sheaves reduce wear and tear

- Extremely convenient open-front design for easy access

- Extended runway length for servicing

- Longer approach ramps for low ground clearance vehicles

- Electric / hydraulic power system

- Runways include rail-kit for optional accessories

- Runways adjust for different tread widths

- Automatic leveling system with multiple auto-leveling locking positions

- Single hydraulic cylinder mounted underneath runway

- Fully enclosed lifting cables, safety locks, and sheaves

- Internal anti-sway slider blocks in each column

- Pneumatic push-button safety release

- Features heavy-duty 1/2" aircraft cable

- Safety locks enclosed in columns minimize pinch points

- Oversized sheave diameter reduces cable fatigue

- Runways feature a durable matte finish

- Rugged, self-lubricating cable sheaves

- Features 1-3/8” sheave axles

- Multi-position safety locks in each column

- Independent backup slack-cable safety latches

- Includes fully adjustable lock stops for precise leveling

- Integrated rolling bridge airline kit option available

- Roll-back kit options available

- Optional drive-thru ramps available

- Optional drip trays available

- Optional 7,000-lb. capacity rolling jacks available (Model RJ7W)

Capacity

Rise

Minimum Wheelbase

Locking

Power Unit

Shipping

Note: An air supply (minimum: 30 psi / 3 CFM) is required for the safety-lock mechanisms to disengage. It is solely the responsibility of the end-user to provide, install and maintain the air supply.

Note: Not all BendPak lift models meet the standards as prescribed by ANSI/ALI ALCTV-2017 or ANSI/UL 201. Consult www.autolift.org for a complete list or contact BendPak via contact@bendpak.com.

BendPak lifts are supplied with concrete fasteners that meet the criteria of the American National Standard ANSI/ALI ALCTV-(Current). Buyer is responsible for all charges relating to any special regional structural or seismic anchoring requirements specified by any other agencies or codes such as the Uniform Building Code (UBC) or International Building Code (IBC).

WARNING: California Prop 65